HOW DO YOU MAKE 'CHIP FREE' CUTS IN LAMINATE /

FORMICA COUNTER TOPS?

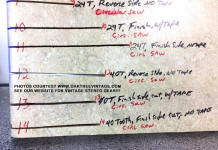

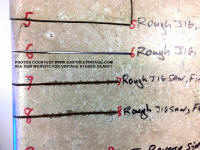

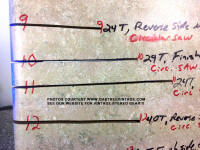

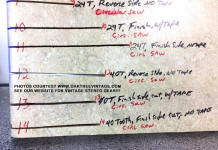

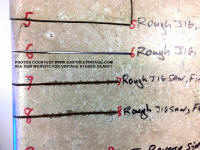

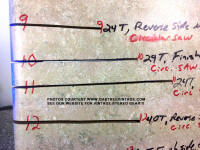

THESE ARE PHOTO EXAMPLES OF CUTS WE MADE TO A FORMICA

COUNTERTOP TO DETERMINE WHICH METHOD WOULD WORK FOR US TO FINISH OFF THE

'END' PRIOR TO INSTALLING THE FORMICA END-TRIM

We had either a

'Jig Saw' or a 'Circular Saw' to utilize (yes, we had Table Saws (both

Large / 10" belt drive, Old Shooool, 200lb Craftsman, and a portable

Delta 10" Direct Drive, a 12" Hitachi Miter Saw (non-sliding), and a 10"

Radial Arm Saw, but none of them were large enough to cut the entire

depth of the counter top in 'one pass'. We utilized Jig Saw and Circular

blades that we already owned, and also purchased some 'finer toothed'

blades for both, as well as 'Reverse Toothed' blades for the Jig Saw,

that were specifically for cutting Formica / Laminate counter tops

. We

did combinations of cuts with both saws with different blades. Some were

cut from the 'finish' side, some were cut from the 'back / un-finished'

side. Some were covered with masking / duct tape first, some were not.

The photos should sufficiently explain how each cut was made and show

the results.

. We

did combinations of cuts with both saws with different blades. Some were

cut from the 'finish' side, some were cut from the 'back / un-finished'

side. Some were covered with masking / duct tape first, some were not.

The photos should sufficiently explain how each cut was made and show

the results.

In the end, we

used the circular saw with a '40-tooth'

blade. We choose the circular saw as it would cut a 'straighter

line' than the jig-saw. We also had to make a 'saw guide / jig' to guide

the saw not only in a straight line, but also over the 90 degree bend at

the back. When finished, the cut line was fairly 'chip free'. It could

have been straighter if we had a large enough table saw, or a really

large Radial Arm Saw. (we'll add a photo of the 'saw guide' we made

later.)

Notes:

Always take all

proper, safety precautions when using power tools. Read the owners /

users manuals, wear proper and adequate safety gear such as ear and eye

protection, and understand the proper operation of each tool.