Shipments ready for pick-up...

|

Turntables are one of the more difficult audio components to pack for safe

transit. Having been a dealer for many brands of tables over the past

38+ years,

I know what works and what doesn’t. I have un-boxed many new tables that were

packed using “factory” packing. When tables are shipped from the manufacturer,

they are generally shipped with the platter and the dustcover removed and stored

in recesses, that are molded into their custom made Styrofoam packing, that was

designed by professionals that have researched what works and what doesn’t.

If the turntables original packing materials are available it

is probably best to use those. If the cosmetic quality of the original box is important,

then that box should be put into another box. Unless the original foam

packing is included with a table (and it rarely is) and is intact, custom and

sufficient / appropriate packing must then be made. While every turntable

presents a different packing challenge, there are some basic procedures that we

repeat and so far has resulted in almost flawless success. No system is

“fool-proof” (even factory packaging) and there are likely a few other

variations that will work equally well, maybe better, but not following these or

other appropriate procedures is likely a recipe for failure.

We typically ship large items

such as turntables via Fed Ex / FedEx or UPS ground (we use USPS / Post Office

/ Postal Service generally for smaller items).

Prior to the packing, the table is prepped for packing. If it is a

“single play” type table, the platter is removed. The platter can weigh

anywhere from a pound or two to as much as 10 or 20 lbs. As a “static” load

this isn’t too bad, but when being dropped from a stack of boxes,

a shelf in the delivery truck,

or even from a hand truck / dolly toppling over, a 4 lb platter can

pretty easily reach a weight in motion of 40 lbs. Much more weight than the

plinth and spindle / bearing were ever designed to handle. Leaving the platter

in place will generally result in a bent spindle,

distorted bearing, busted plinth

or a combination of these. We’ll talk about what is done with the platter and

rubber mat later. Next if there are any transport screws (not as common on

single play turntables as changers, but may still be used) they should be

installed /

engaged. Some single-play tables may have had transport screws, but they

were

usually removed for use and subsequently misplaced or

discardedt. Suitable replacements

should be obtained and installed unless other ways of stabilizing the suspension

are available such as the use of shims. On changer / stacker type tables or

tables that need their suspension secured, and if the locking screws are not

available, then 5” shrink film is used to secure the platter and / or suspension

in place (done with dust cover removed). Also on stacker type tables, the long

play spindle is removed if practical. If available the “short-play” spindle will be installed

prior to the shrink wrap operation as this is a great place to “store” it for

shipment. The long-play spindle will be bagged and packed safely on it’s own.

The tone-arm is then secured in place in it’s “locked” position with a

twist tie, painters tape or other

adequate means.

The counter-weight is either then removed and packed separately or

supported in place

by foam if it is not 'practically' removable. Many

styluses and dust-covers are damaged / destroyed by counter-weights flying

around inside that were not secured. Next the dust-cover is reinstalled if it

had been removed. A thin sheet of “poly-lam” foam is placed in

between the turntable base and the dust cover. Next the dust-cover is VERY FIRMLY secured in place with

stretch film from every direction. Once sealed down the turntable and

dustcover becomes a solid unit. No motion is allowed or loose

parts should be detected (we invert the table and shake it up and down to make

sure of that).

Next, our tables are usually,

housed in a

1.5" and 2" sheet foam "box"

(these are foam sheets made for house insulation and available at most home

improvement stores),

cut and assembled to fit exactly. Once the table is sealed and there are

no parts inside "rattling around" to break things or scratch the dust cover, the

foam 'box' is built around it.

On tables that have suspension built into the feet, small depressions need

to be "dug" in to the foam where the feet are, so that the tables weight is not

on the feet for shipping. The feet's own

internal suspension is not sufficient for this

protecting the unit in transit. Any "play" or

space inside the foam box, should be filled with foam

or bubble wrap. Typically there is room for a sheet of 1/2"

bubble wrap on the top. Then a top plate of 2", 'high-density'

(the expensive, pink type) foam is

sealed down tight to the rest of the foam box with the

stretch film. The platter and rubber mat are usually stretch filmed to the top of the

box taking care to make sure the mat is not bent or allowed to bend / wrinkle.

The best way to ensure this is to place the mat down first on the box, then

cover it with the platter positioned up-side down, to hold it in place.

If there are any protrusions from the back of the platter,

make sure the box will be large enough to allow plenty of loose fill packing to

protect the platter. This is then stretch filmed in place on the top of

the foam box. Once the foam box is finish packed, it is then suspended inside

the outside box, using loose fill packing (foam

peanuts).

We ship about dozens of tables a year (about 750 units

/ packs

total a year) and have a virtually spotless track record. From the "un-scientific" survey we have done from

customers calling / emailing for parts / insurance claim amounts on units

shipped from amateur sellers / packers, we see an extremely high failure rate on

electronics / tables / reel to reel machines. I have a customer who recently

ordered 10 tables as an experiment

(yes he has a lot of money

to throw around) mostly from all different sellers and he said

of the 10, only 4 came in

essentially undamaged

and given the way they were packed, they should have ALL likely been damaged.

Our philosophy is that if something gets damaged in transit, it's almost

ALWAYS

due to inappropriate packaging and not likely the fault of

the shipper / transit company (UPS, FEDEX, USPS etc). Everyone should know

that a package will be dropped, thrown, kicked, subject to thermo nuclear

war etc, so it should be packed to withstand any possible scenario! The worst thing about this is that the world has

lost a lot of really cool vintage gear due to inadequate /

inappropriate packing by sellers who are inexperienced in the proper

procedures, or lack adequate materials to do so. :-(

PS. For years I hear folks preaching that electronics must be

'Double Boxed'. I've even seen that listed on either the FedEx site or UPS's

Site (I don't remember which)..... BS !....In all the years I worked on

the retail floor, un-boxing many thousands of pieces of gear, I can count on

less than one hand the number of times I've seen manufactures 'double box'

anything. You could put something in ten boxes, but if it's not packed inside

the first box correctly, it won't likely matter!

|

MORE INFO AND PHOTOS WILL BE

POSTED

|

DUAL 500 SERIES TURNTABLE

The tone-arm is then tied in place in it’s “locked” position

with a wire tie on the Dual 500 series.

|

...or held in place with suitable measures such as on the

this B&O Beogram 3000.

|

The smaller, lighter weight accessories can be tied

to the tone arm stand / lock as long as they're limited to an ounce or

two. Accessories such as cartridge containers, single play spindles, 45

adapter discs, strung style anti-skate weights (not the counter weight!)

etc.

|

Photo of Dual 500 series above.

Next if there are any transport screws (not as common on single play

turntables as changers, but may still be used) they should be engaged,

which usually means turning them counter-clockwise to their “out”

position. Some single-play tables may have had transport screws, but they

are usually removed for use and subsequently have been lost.

Suitable replacements will need to be acquired. We have an assortment of

any diameter / length we would need on hand.

|

Transports screw in "locked" up position for shipping.

Another version of transport / shipping lock downs;

|

Occasionally on belt drive / rim drive turntables the

motor will utilize it's own transport lock bolts. If so, appropriate

bolts will need to be sourced and installed.

|

Photo Sansui stereo

turntable SR/4040

Prior to the packing, the table is prepped for packing. If it is a

“single play” type table, the platter is removed. The platter can weigh

anywhere from a pound or two to as much as 10 or 20 lbs. As a “static”

load this may seem like an insignificant amount, but

as a 'dynamic load' as in when being dropped from a

stack of boxes or a delivery truck, a 4 lb platter can pretty easily reach

a weight in motion of 20-80 lbs. Much more weight than the plinth and

spindle / bearing were ever designed to handle. Leaving the platter in

place will generally result in a bent spindle, warped bearing, busted

plinth or a combination of these. A platter left in

place on most turntables will result in damage to the dust cover and the

tone arm assembly from 'flying around freely' inside the now damaged /

ruined dust cover. I have heard of tone-arms completely busted or broken

off from this. We’ll talk about what is done with the

platter and rubber mat later.

(Photo shows internal & integrated platter and not the main

"heavy" platter that has already been removed. In this case

stabilizing shims were added to the internal platter

which was not practical for user to re-install once delivered. If the

smaller platter weighs much more than a half pound or so, then it too

should be removed)

|

|

|

The counter-weight should then

be removed (if

practical) and packed separately. If it can't be

'practically' removed, then it should be held in place by foam. Many styluses and dust-covers are damaged /

destroyed by counter-weights flying around inside that were not secured

or removed. If there is absolutely no way to

remove the counter weight, then it's a good idea to block / restrict

it's movement by sufficient means. We have actually seen the rear tube

of tone arms that have been broken due to a counter weight's mass.

Again, it doesn't seem like much, but when dropped from 3-5 feet, at the

right angle and it can snap the tone arm.

|

|

Photo Marantz 6100 series

This was a turntable that arrived to us as a

'trade-in'. While in this case it did arrive intact, and no damage was

done, the counter weight should have been removed and packed separately.

There's no reason on this table not to have done that, and frankly

probably would have been easier than what the person did.

|

Photo Sansui SR/4040

Stereo Turntable

Foam pad added between dust cover and integrated platter

that was not 'practical to remove' for further

protection.

|

Next the dust-cover is VERY FIRMLY secured in place with shrink film

from every direction. Once sealed down the turntable and dustcover becomes

a solid unit. No motion is allowed. Most turntables

will also have a sheet of 'poly lam' foam between the dust cover and the

plinth to absorb shock. If this technique is utilized (and it should and

usually is), care must be taken to not allow damage to cantilever in

transit or during unpack from the foam sheet.

Photo Technics SL-Q2

Pioneer PL-55DX dust cover secured w/ 'polylam' foam

to absorb shock

|

Photo B&O Beogram 3000 Turntable

|

Photo B&O Beogram 3000

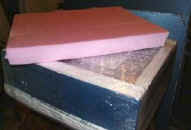

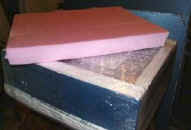

Next, our tables are always, housed in a 2" sheet foam

"box" that fits exactly. Once the table is sealed and there are

no parts inside "rattling around" to break things or scratch the

dust cover, it is put into the foam box. On some tables that have

suspension built into the feet, small depressions need to be

"dug" in to the foam where the feet are, so that the tables

weight is not on them for shipping. The internal suspension is not

sufficient for this.

|

Photo B&O Beogram 3000

Photo Technics SL-Q2

|

Photo B&O Beogram 3000

|

Photo Technics SL-Q2

If there's no dust cover, then

foam must be stacked to protect tone arm.

|

Photo Technics SL-Q2

|

Photo Technics SL-Q2

|

Photo Sansui SR/4040 stereo turntable

Any "play" or space inside the foam box, will be filled with

foam or bubble wrap.

|

Photo B&O Beogram 3000

A sheet with specific un-packing / re-assembly instructions included with

every table.

|

Photo B&O Beogram 3000

Photo Technics SL-Q2

|

Then a top plate of 2", high-density “pink” foam is sealed

tight to the rest of the foam box with the stretch film. Prior to that if

there's any space between the top of the dustcover and the foam

"lid" that should is also filled to eliminate

up / down movement. We generally use a small sheet

of 1/2" bubble wrap to do that.

|

|

Photo B&O Stereo Turntable Beogram 3000

The platter and rubber mat are stretch filmed to the top of the box

taking care to make sure the mat is not bent or allowed to bend / wrinkle.

The best way to ensure this is to place the mat down first on the box,

then cover it with the platter positioned up-side down, to hold it in

place. This is then stretch filmed in place on the top of the foam box.

|

Photo Technics SL-Q2 Stereo Turntable

The platter and rubber mat are stretch filmed to the top of

foam box / housing. Also

present is the counterweight 'dug' into a recess and a sheet containing

all instructions for unpacking, set-up, adjustment and our contact info

for assistance.

|

Pioneer PL-55DX ready to place in

final shipping contanier

|

|

|

Once the foam box is finish packed, it is then suspended inside the

outer box, using loose fill (foam peanuts).

Photo prior to covering the top and sealing the box.

|

Ready to Ship!

We ship about 50-60 tables a

year (about 750 units / packs total a year) and have

a

virtually spotless track record. On an

interesting side note; I have a customer

/ collector who

recently ordered 10 tables (mostly from all different sellers) and he said

6 came in damaged due to inappropriate packaging.

2 had damage that 'appeared' to be from lack of packing, but could have

existed prior to shipping. 2 fared decently, but by only luck as NONE were

packed appropriately. The worst thing about

this is that the world has lost a lot of really cool vintage gear:-(

|

|

MORE TO COME AS TIME ALLOWS

|

|

Yes, we should all know by now that 'stuff' happens. FedEx or UPS or the

Postman or 'Joes delivery service' will 'drop' packages. There is

simply not enough time for 'carriers' to 'coddle' every package with 'kid gloves' and

accidents happen. They'll fall off conveyer belts, have other packages

fall on them, get 'drop kicked', be used as soccer balls, fall off the

hand truck, fall out of the back of the truck, be involved in

'thermo-nuclear war', etc. They need to be packed so all of that and

more can happen, and still arrive intact and unscathed!

If you can't

pack items to that degree, then you probably shouldn't be selling /

dealing in / packing /

shipping them. Sorry, but the world is loosing too much irreplaceable

gear and too many units due to amateurs.

If I've offended anyone then

that probably means you.

What qualifies me to to 'be the expert'?

Having unpacked hundreds (maybe even thousands at this point) of electronic units for store

displays, demo's, unpacked and re-packed for tent sales, events, RTV,

customer inspections, etc, not to mention my own use for the past 38+

years of doing this has shown me how the manufacturers do it.

Having

shipped ~16,000 units over the past 38+ years, most of which had

to have packaging re-designed / fabricated from scratch, with only 1 or

2 minor damage issues (no, I'm not kidding) pretty much makes me an

expert and the one you should probably be listening to.

"Wow, you sound really arrogant!"

I'm OK with that!

Sorry, but vintage audio gear, damaged due to inappropriate, inadequate,

unprofessional packing is my biggest 'pet peeve'.

|

LINKS TO OUR 'HI-FI' DEPARTMENTS

Wondering where

the "tone" you remember went?....

.... Surround yourself with Silver and find it again!

|

| - |

-

|

-

|